Anker Innovations has announced the launch of the AnkerMake M5 – a 3D printer “designed to improve the user experience by reducing printing time up to 70%.” According to AnkerMake, the M5 makes 3D printing more accessible as it is designed is easy to set up in just three steps within 15 minutes.

It has several user-friendly features including 7×7 auto-levelling, PEI soft magnetic printing bed, auto-resume after power outage and printing notifications, the company says. These enhancements are said to help the user focus completely on their prints instead of technical aspects and handcrafting.

A new standard in print speeds

Thanks to its new PowerBoost technology, the AnkerMake M5 basic print speed is 250 mm/s (9.84 inches per second) , which can be used for printing jobs that require a smoother and more detailed finish, Anker claims. For faster print jobs, the M5 can save even more time with an acceleration of the extruder up to 2,500 mm/s² (98.4 inches per second) . In this print mode, the M5 can, says the manufacturer, reduce the average print times by up to 70% in comparison to other 3D printers.

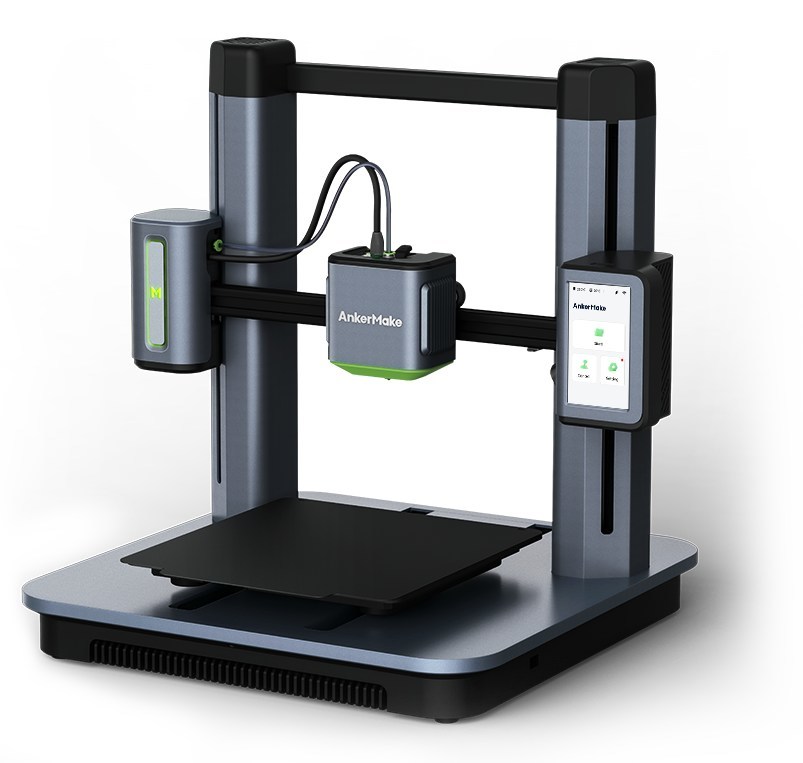

Stable, quality printing

The aluminum alloy die-casting design increases the weight of the base, reducing the center of gravity of the machine. The sleek design promises to make printing more stable and allows fast speeds and extreme acceleration. According to Anker, the installation error of the base is also reduced, improving the accuracy of the printing tool and surface even at high speeds with 0.1 mm precision.

AI print monitoring

Users can also view live feeds of their print jobs from anywhere using the AnkerMake mobile app, and time-lapse videos are automatically generated after the printing job is complete. With an adaptive light-sensing algorithm, users can see the printer output clearly, even at night, the company says.

Smart, Connected Printing

The AnkerMake M5 can be connected and controlled through both the AnkerMake mobile app and AnkerMake slicing software1. Multi-device management and remote messaging notifications enable the user to start printing from their smartphone or computer anytime, anywhere.

Steven Yang, CEO of Anker Innovations, commented: “3D printers help us imagine a world where ideas and creative concepts can be instantly transformed into physical form. However, the reality is 3D printing can be slow, cumbersome, and difficult to figure out. AnkerMake is committed to removing these pain points so that artists, inventors, hobbyists and DIY enthusiasts can take advantage of a more practical tool to bring their creations to life.

“The AnkerMake M5 solves the most critical issues that have prevented 3D printing from becoming a more mainstream endeavor. These issues include slow print speeds, the need to constantly supervise printing for errors and a needlessly complicated user experience.”

Additional Specifications to the above include: 5X industry average print speed (250 mm/s in standard print mode), 2,500 mm/s² in accelerated print mode, AI print monitoring with auto shut-off, plus it supports WiFi and USB connectivity.

The MD also offers easy filament loading and extraction with heat assist and has a magnetic base for easy removal and cleaning. It weighs 12.4 kg / 27.3 lb and measures 502x438x470 mm / 19.76×17.24×18.50 inches.

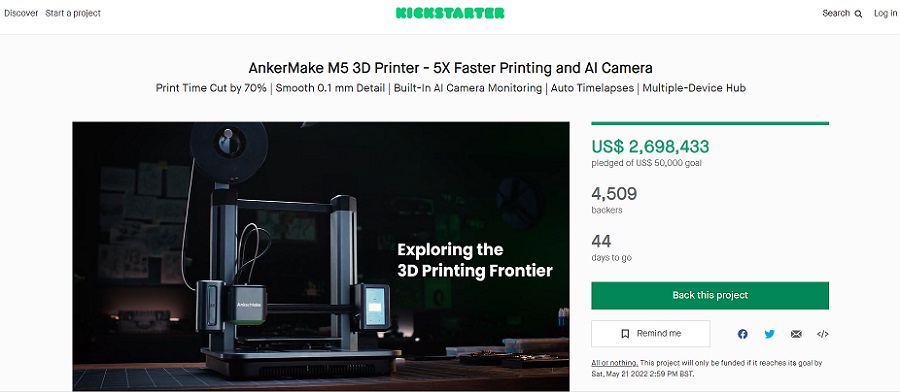

The AnkerMake M5 3D printer is available on Kickstarter.com starting today for special, limited super early bird price of US$429 (approx. €395). The normal early bird price is US$499 (approx. €458).

The AnkerMake App and software will be available later this year at the commercial launch of AnkerMake M5.

Key Selling Points

- PowerBoost technology for faster print speeds of 250 mm

- 7×7 auto-levelling

- Watch jobs being printed from anywhere via mobile app

Click here to read the original version of this story on IFA News Room.